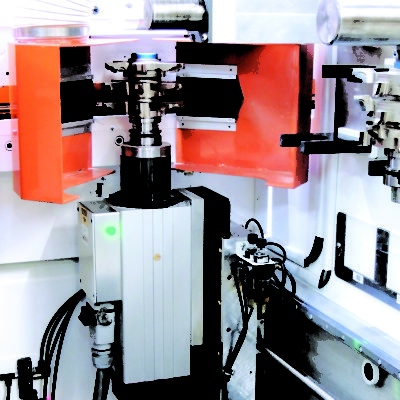

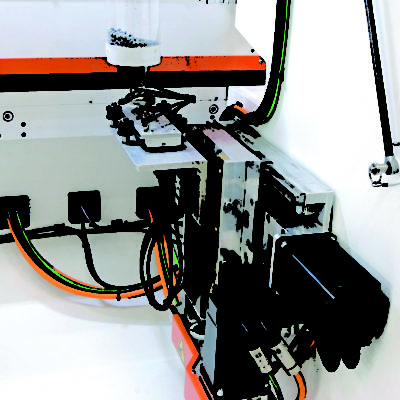

Voorwood designs and manufactures innovative, high-quality, precision-made woodworking machinery which includes single- and double-end tenoner machinery. Voorwood’s tenoner machinery is suitable for use in the manufacture of kitchen cabinets, furniture, solid-surface, and by specialty wood industries to shape and sand profiles of raised panels, outside edges, coping, stiles, and rails. Voorwood machines are capable of CNC (Arch) contouring during the pass-through process. Voorwood engineering customizes the woodworking machinery to meet your process requirements.

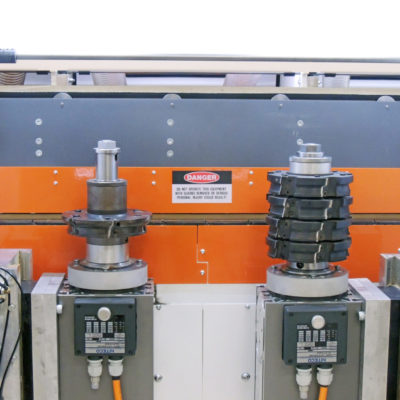

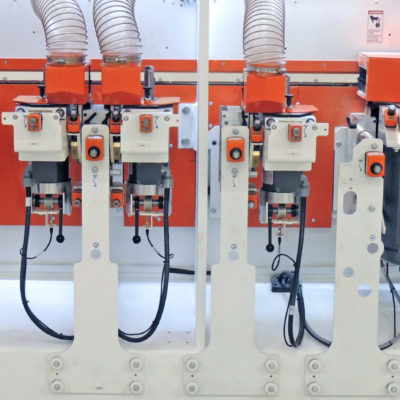

OPTIONS: Hopper feeder; Automatic space ball inserter; Spindles configured with quick change, HSK, or stacked tooling; Fully automatic tool changers; Automatic size and square.

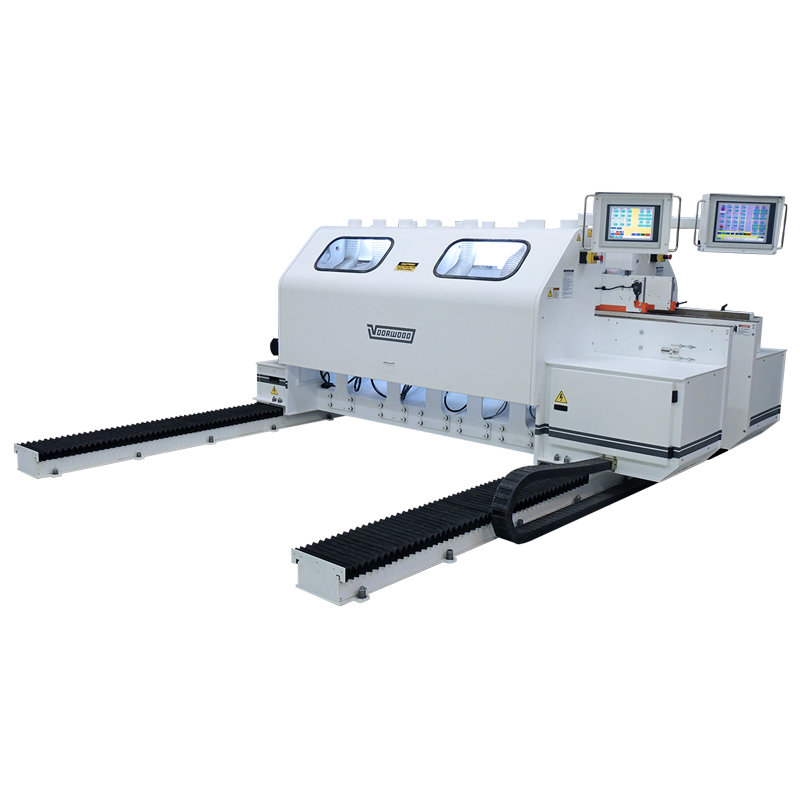

Double-End Tenoner Series: Shapes and sands/polishes two edges in one pass of hardwood, MDF, and solid resin based substrates. Capable of CNC (Arch) contouring during the pass-through process.

A2500 SERIES

Automatic setup • Most throughput in the industry • Processes the smallest part in the industry • Accurate/automatic sizing and squaring • Capable of CNC contouring (arching) on one or both sides

A200 SERIES

Manual adjustment series designed for fast and repeatable set up

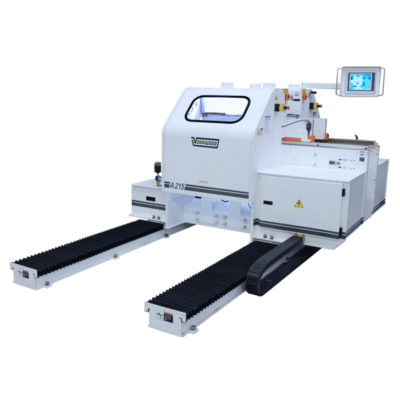

Single-End Tenoner Series: Shapes and sands/polishes edges in one pass of hardwood, MDF, and solid resin based substrates. Capable if CNC (Arch) contouring during the pass-through process.

A1500 SERIES

Axis configuration allows for best repeatability • Processes smallest parts in industry (1.50” W x 3.50” L) • Servo controlled automatic positioning • Automatic tool changer • Capable of producing contoured parts (arches) • Designed to meet your R.O.I.

A500 SERIES

Capable of producing contoured parts (arches) • Manual setup designed for fast and repeatable tool change • Simplest and easiest control system to operate • Capable of producing a contour every 2 to 5 seconds!