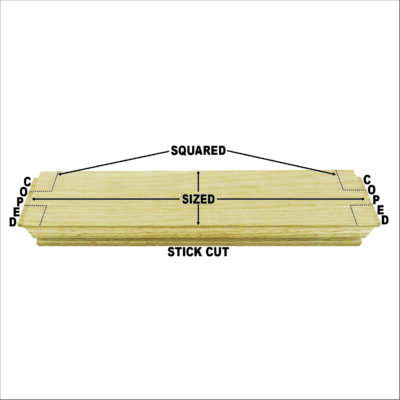

Voorwood cope machines support the production of doors in the woodworking industry. Our cope shapers are available in several models starting with a single-side dual spindle cope shaper to double-side cope shapers with full CNC automatic positioning for the best possible repeatability and fastest throughput in the industry. Our cope machines support either S4S or profiled parts without needing a backer block for eliminating tear-out.

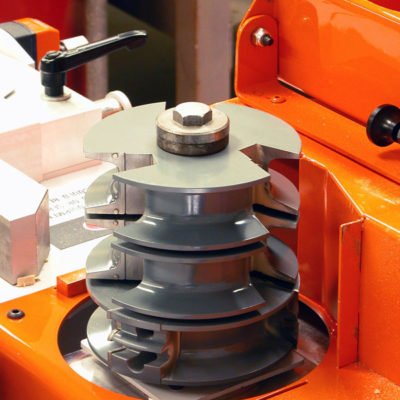

OPTIONS: Hopper feeder; automatic space ball inserter; spindles configured with quick change, HSK, or stacked tooling.

TOTAL DOOR SYSTEMS DESIGNED FOR FAST AND REPEATABLE SETUP

A15 Stile & Rail Tenoner: Hopper feeds, profiles, sands, and automatically inserts space balls into style and rail components of cabinet or entry doors.

A26 Cope Shaper: Designed to shape single or multiple parts in one pass. Parts can be quickly transferred from left or right shapers for end-to-end cope cuts. Both edge guide assemblies are removable which allows cope cuts on parts longer than 36 inches.

A16 Cope Shaper: Designed to shape single or multiple parts in one pass. Dual counter-rotating shapers on a rack and pinion drive assembly.