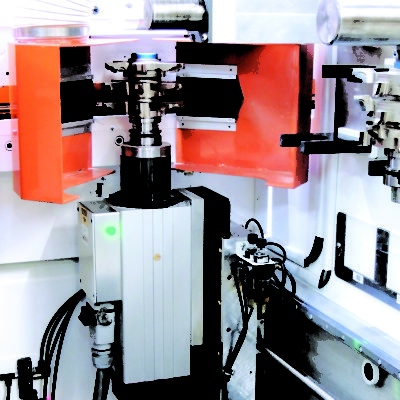

Voorwood designs and manufactures innovative, high-quality, precision-made woodworking machinery which includes tenoner machinery, shaper sanders, miter machines, stile and rail shapers, cope shapers, and miter lock shaper. Voorwood hardwood woodworking machinery can be used in the manufacture of kitchen cabinets, furniture, solid-surface, and specialty wood industries. Voorwood hardwood machines are used to shape and sand profiles for raised panels, outside edges, coping, miter, and stile and rails. Capable of CNC (Arch) contouring during the pass-through process. Voorwood engineering customizes the woodworking machinery to meet your process requirements.

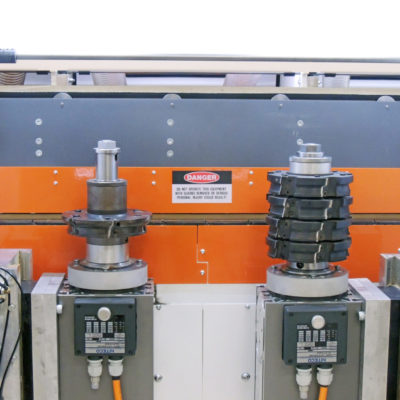

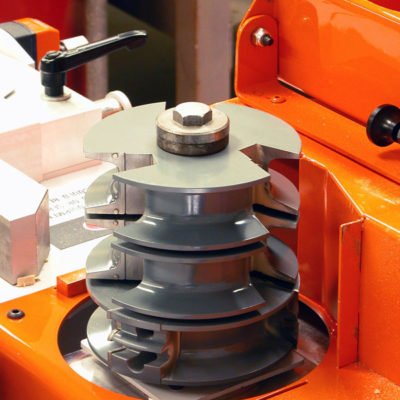

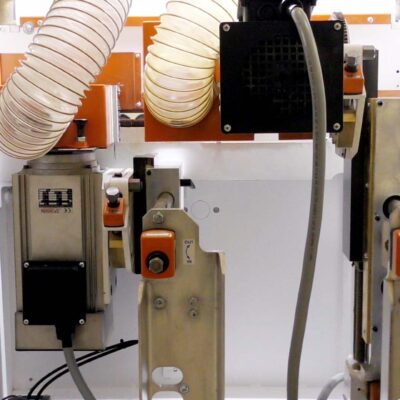

OPTIONS: Hopper feeder; Automatic space ball inserter; Spindles configured with quick change, HSK, or stacked tooling; Fully automatic tool changers; Automatic size and square.

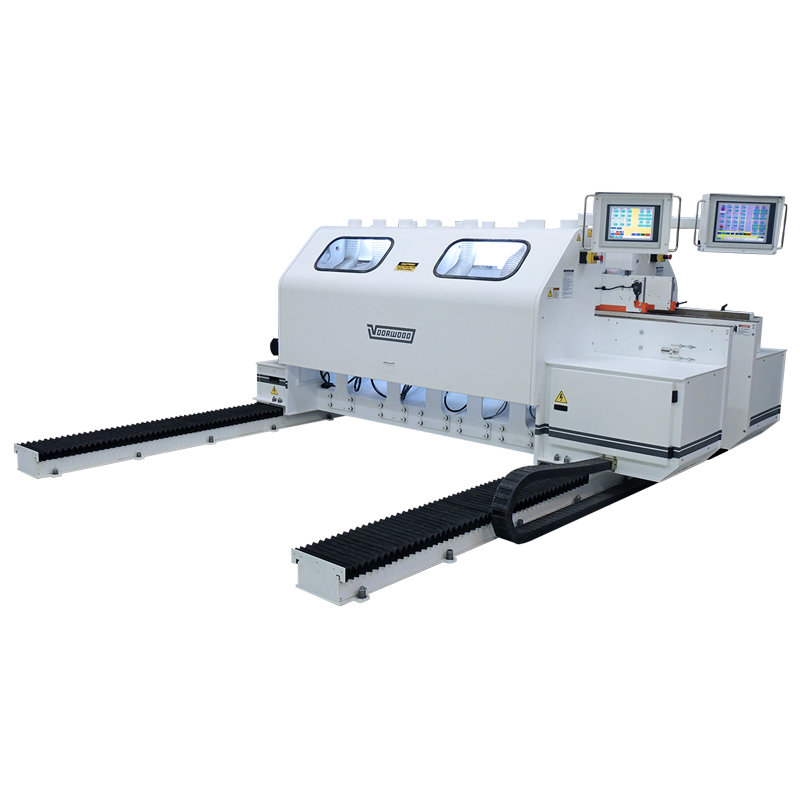

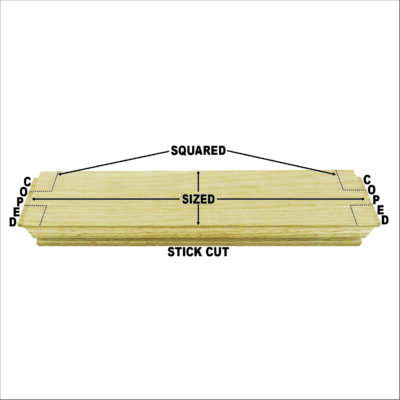

Double-End Tenoner Series: Shapes and sands/polishes two edges in one pass of hardwood, MDF, and solid resin based substrates. Capable of CNC (Arch) contouring during the pass-through process.

A2500 SERIES

Automatic setup • Most throughput in the industry • Processes the smallest part in the industry • Accurate/automatic sizing and squaring • Capable of CNC contouring (arching) on one or both sides

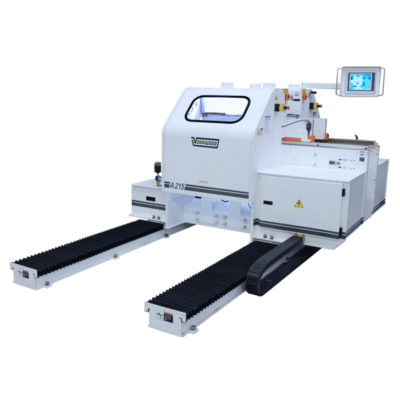

A200 SERIES

Manual adjustment series designed for fast and repeatable set up

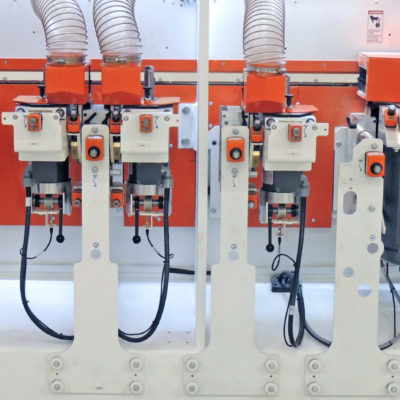

Single-End Tenoner Series: Shapes and sands/polishes edges in one pass of hardwood, MDF, and solid resin based substrates. Capable if CNC (Arch) contouring during the pass-through process.

A1500 SERIES

Axis configuration allows for best repeatability • Processes smallest parts in industry (1.50” W x 3.50” L) • Servo controlled automatic positioning • Automatic tool changer • Capable of producing contoured parts (arches) • Designed to meet your R.O.I.

A500 SERIES

Capable of producing contoured parts (arches) • Manual setup designed for fast and repeatable tool change • Simplest and easiest control system to operate • Capable of producing a contour every 2 to 5 seconds!

A100 SERIES

For profiling straight edges • Manual setup designed for fast and repeatable tool change • Simplest and easiest control system to operate

TOTAL DOOR SYSTEMS DESIGNED FOR FAST AND REPEATABLE SETUP

A15 Stile & Rail Tenoner: Hopper feeds, profiles, sands, and automatically inserts space balls into style and rail components of cabinet or entry doors.

A26 Cope Shaper: Designed to shape single or multiple parts in one pass. Parts can be quickly transferred from left or right shapers for end-to-end cope cuts. Both edge guide assemblies are removable which allows cope cuts on parts longer than 36 inches.

A16 Cope Shaper: Designed to shape single or multiple parts in one pass. Dual counter-rotating shapers on a rack and pinion drive assembly.

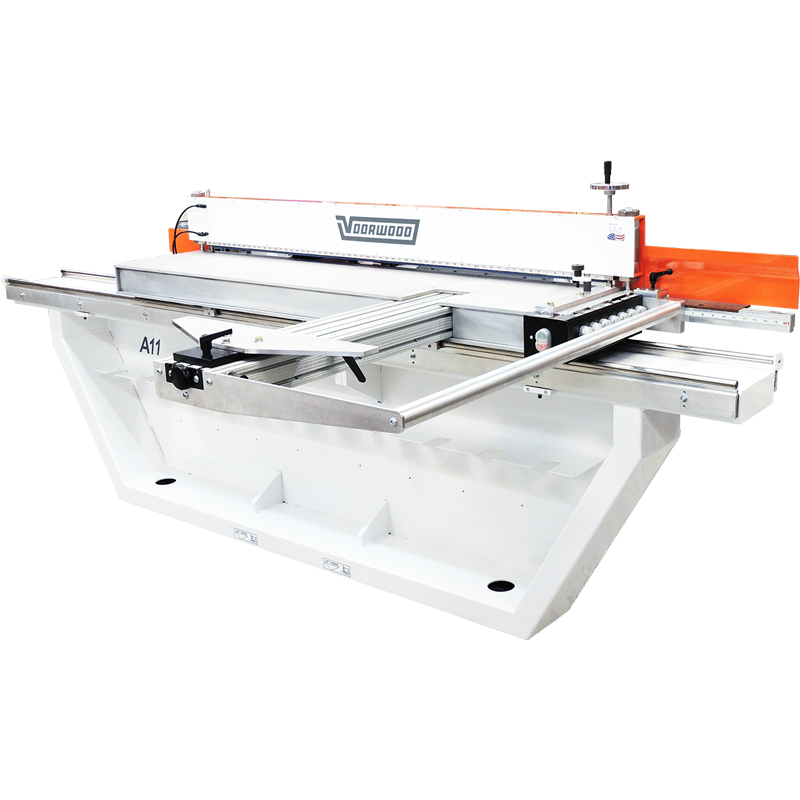

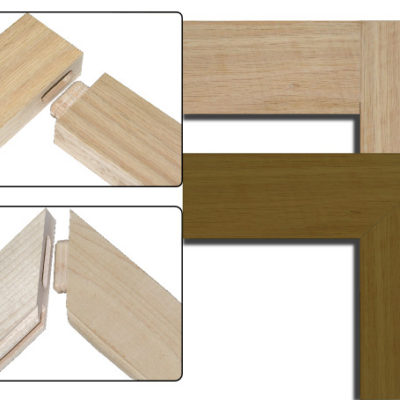

A11 Table Shaper Sander: Profiles and sands the edge of wood components. The A11 is capable of processing all the components of a five piece door and is capable of shaping and sanding straight components as well as contoured shapes using a template system. The A11 is also equipped with a back gauge and edge guide for sizing and squaring wood substrate as it is being processed

A12 Miter Lock Shaper: Profiles precision miter lock joints from 90° to 150° in solid wood and plywood substrate in one pass.

Miter Machines: Designed to rapidly create mortise and tenon cuts at 0, 45 and 90 degrees for face frames and standard miter doors.

M SERIES