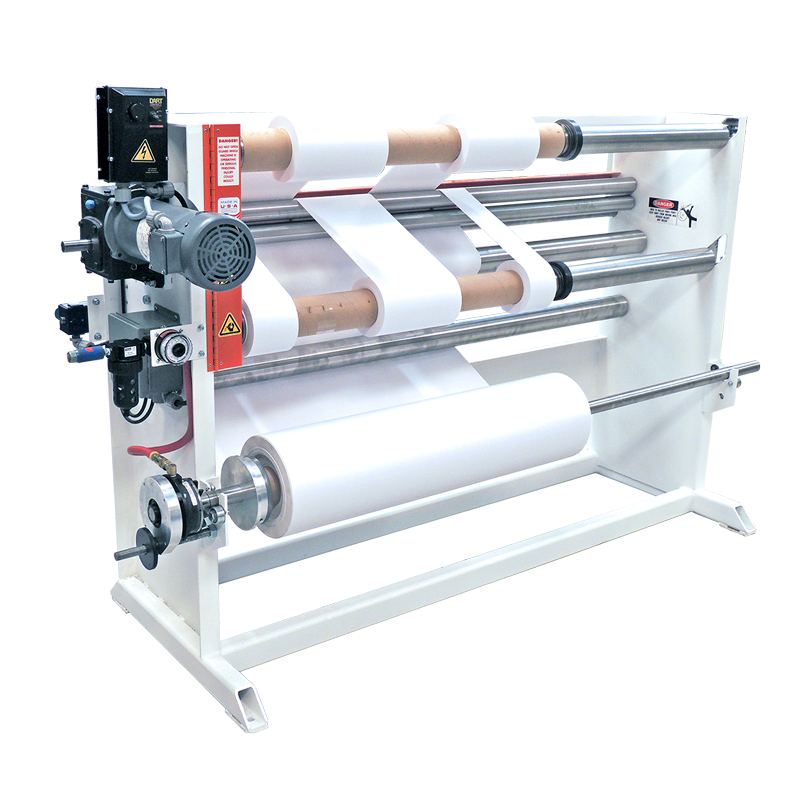

Voorwood designs and manufactures innovative, high-quality, precision-made slitter rewinder machinery which includes duplex slitter rewinders. Voorwood slitter rewinders can be used for the following applications in converting paper and paper board, foil, tape, plastic film, labels, pressure-sensitive laminates, flexible packaging, nonwovens, rubber, and specialty materials. Voorwood engineering customizes the converting machinery (slitter rewinder) to meet your process requirements.

Slitter Rewinders ● Duplex Center Slitter Rewinders ● Paper Rewinders ● Rewinder ● Rewinder Slitter ● Rewinder Machine ● Slitter Machinery

OPTIONS: Laser Core Positioning, Full Lay-on Rollers, Individual Lay-on Rollers, Bow Rollers, Chevron Rollers, Cleaning Rollers, Static Rollers, Core Locking Differential Rewind, Standard Differential Rewind with Spacers, Leaf Rewind, Automatic Web Tension Control, Rotary Shear-, Score- and Razor-Slitting, Automatic Roll Offload Pusher, Unload Fork Assembly, Cantilever Rewind Shafts, Lift-Out Rewind Shafts, Hydraulic Lift Loader Unwind, Shaftless Rear Unwind, Shaftless Front Unwind, Splice Table Assembly, Automatic Servo Knife Positioning, Digital Readout Anvil Positioning, Static Control Bar, Selvage Eductor (Vacuum Trim System), Trim Oscillating Rewind, Safety Fences or Programmable Laser Scanners, Corona Treatment Unit, Perforator Unit

C/CX/CR Series Slitter Rewinder: Duplex slitter rewinder series designed and manufactured primarily for high-speed winding of vellum, papers, and polyester films.

C SERIES

CX SERIES

CR SERIES

CA Series Duplex Slitter Rewinder: Cantilever design for slitting different substrates up to 27″ wide.

CA SERIES

6215 Slitter Rewinder: This is an economical duplex slitter rewinder for unwinding, razor slitting, and duplex rewinding rolls up to 15″ in diameter.

6215 SERIES