Hardwoods

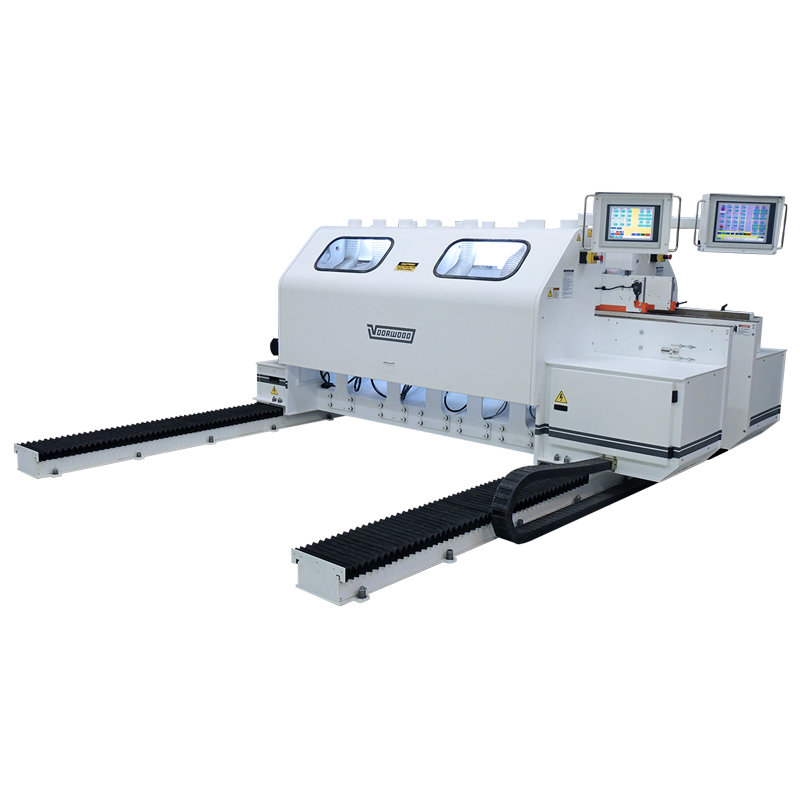

A2517 DOUBLE-END TENONER

The A2517 Double-End Tenoner is fully equipped to automatically position all necessary adjustments for each profile setup. All spindles are of the reversing type and set up to rotate with or against the direction of feed, with a jump feature on the first station. The sanding stations have reversing spindles on each side.

A2515 DOUBLE-END TENONER

Automatically makes all necessary adjustments for each profile setup. All spindles are set up to rotate with or against the direction of feed with a jump feature on the first station. The sanding stations have reversing spindles on either side. The stations can be horizontally locked for straight shape/sand or CNC controlled to shape/sand arches.

A5615 AUTOMATIC DOUBLE-SIDE COPE & STICK SHAPER

Will process stiles and rails without operator input. Substrates are hopper fed random length parts. Automatically measures the rail substrate and selects the desired finished length without any operator input or downloaded cut list. The rail is placed in the dual timed cartridges with self-locating backer blocks that eliminate blowout.

A2515 DOUBLE-SIDE COPE SHAPER

Equipped with mirrored shaping stations on either side that automatically position all necessary adjustments for each profile setup. All spindles are reversing and set up to rotate with or against the direction of feed with a jump feature on the first station. This cope shaper is equipped with variable-speed transporter drive motors.

A215 DOUBLE-SIDE COPE SHAPER

Equipped with mirrored shaping stations on either side. The first station has the option to be configured to jump in or out during the cut and includes automatic CNC control of the horizontal axis for the best possible repeatability. Servo positioning is accurate within.002”. The second unit rotates against the direction of feed to finish the cut.

A217 DOUBLE-END TENONER

Profiles and sands both edges of hardwood parts in one continuous pass. Depending on model configuration, each side of the machine is comprised of up to three shaping units that make the same cut to prevent end grain tear-out. The first shaper rotates with the feed direction.

A215 DOUBLE-END TENONER

Profiles and sands both edges of hardwood parts in one continuous pass. Each side of the machine is comprised of two shaping units that make the same cut to prevent end grain tear-out. The first shaper rotates with the feed direction. As the substrate passes, the station jumps in to make a short but full depth cut on the substrate’s trailing edge.

A1517 SINGLE-END TENONER

Can accommodate five or more stations with identical HSK-63F spindle motors, to be used in any configuration of shaping and sanding. All spindles are reversing and set up to rotate with or against the direction of feed with a jump feature on the first station. The stations can be horizontally locked for straight shape/sand or CNC controlled.

A1515 SINGLE-END TENONER

Can accommodate four stations with identical HSK-63F spindle motors, to be used in any configuration of shaping and sanding. All spindles are reversing and set up to rotate with or against the direction of feed with a jump feature on the first station. The stations can be horizontally locked for straight shape/sand or CNC.

A517 SINGLE-END TENONER

The A517 Single-End Tenoner can accommodate five or more shaping/sanding stations. Clockwise and counter-clockwise rotations are used on specific shapers to eliminate rejects and produce the highest quality finished part. A PLC controlled servo motor drives the shaper horizontally as a function of the transporter speed.

A515 SINGLE-END TENONER

The A515 Single-End Tenoner can accommodate four shaping/sanding stations. Clockwise and counter-clockwise rotations are used on specific shapers to eliminate rejects and produce the highest quality finished part. A PLC controlled servo motor drives the shaper horizontally as a function of the transporter speed to produce a pre-programmed contour.

A117 SHAPER SANDER

The A117 Shaper Sander can accommodate five or more shaping/sanding stations. Clockwise and counter-clockwise rotations are used on specific shapers to eliminate rejects and produce the highest quality finished part. The A117 Shaper Sander can be configured with one to three shaping units to shape outside edges and raised panels.

A115 SHAPER SANDER

Can accommodate four shaping/sanding stations. Clockwise and counter-clockwise rotations are used on specific shapers to eliminate rejects and produce the highest quality finished part. The A115 Shaper Sander can be configured with one to two shaping units to shape outside edges and raised panels.

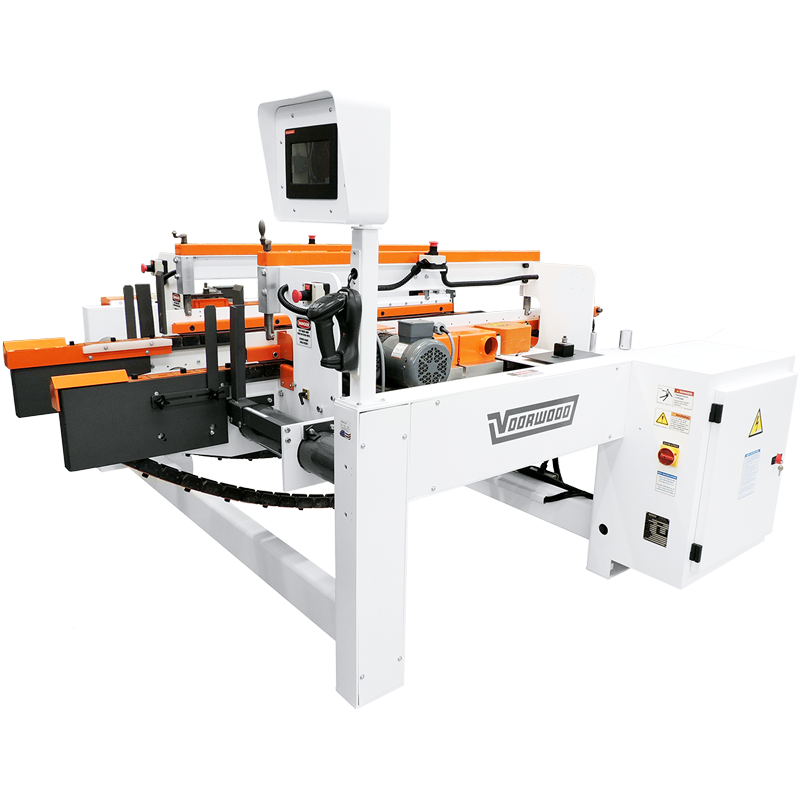

M15 MITER MACHINE

Designed to rapidly make mortise and tenon cuts at 0°, 45°, and 90° degrees. Parts can be up to 1.5” thick and up to 4” wide, and of ANY length. A primary application for this machine is for miter cabinet door frames. Parts can be quickly transferred from left to right. They are mortised on the left side of the machine and tenoned on the right.

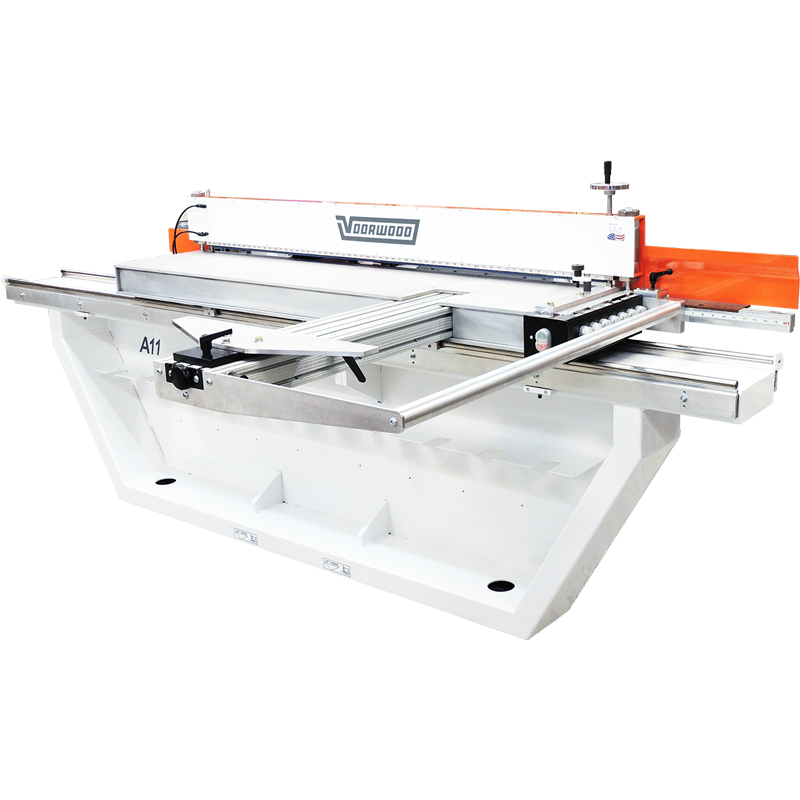

A11 TABLE SHAPER SANDER

The A11 Table Shaper Sander shapes all components of cabinet doors, parts of drawers, and other wooden components and simultaneously sands the desired profiles, sizes the substrate to the desired finished dimensions, squares the substrate as all four sides are being processed, and processes straight edges as well as contoured shapes.

A16 COPE SHAPER

The A16 Cope Shaper with single side dual spindle is designed to shape single or multiple parts in one pass. The cope shaper has an average cycle time of 4 seconds making it a highly productive machine. Designed to run either S4S or profiled parts without the need for a backer block for eliminating tear-out.

A26 COPE SHAPER

Designed to shape single or multiple parts in one pass. Each shaping station is equipped with a precision-balanced drive motor and spindle. The counter-rotating spindles cut against the direction of feed. Spindles can be configured with quick change, HSK, or stacked tooling. Parts can be quickly transferred from left or right shapers.

A15 STILE & RAIL SHAPER

The A15 Stile and Rail Shaper straight cuts inside edges on the stiles, rails, and the outside edges (long-grain). This is the only machine on the market with the capability of shaping small parts. Spindles can be configured with quick change, HSK, or stacked tooling. This system eliminates manual processes and saves labor.

A15 MITER LOCK MACHINE

The A15 Miter Lock Machine shapes the edge of solid wood and plywood parts in one go to produce a precision lock miter joint, thus eliminating the doweling process. The machine has two shaping stations, one in the vertical position and the other in the horizontal position, to accomplish both profiles of the miter lock joint.

A12 MITER LOCK SHAPER

Shapes the edge of solid wood and plywood parts in one pass to produce a precision lock miter joint. Eliminates the doweling process. The A12 Miter Lock Shaper machine’s shaping station is equipped with a precision-balanced drive motor/spindle combination. The spindle is equipped with vertical, horizontal, and tilt adjustments.

Profile Wrappers

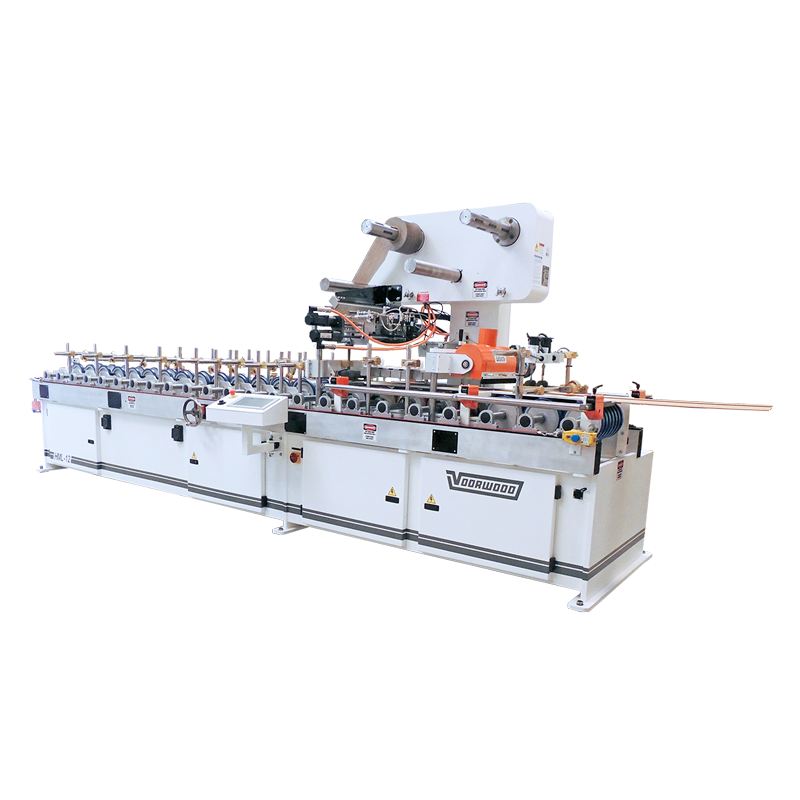

HML 12 PROFILE LAMINATOR

The HML-12 Profile Laminator applies hot melt adhesives to the back of the various paper, foil, or vinyl webbings, and wraps the webbing around all types of profiled wood, extruded plastics, and metal substrates. The base hot melt wrapper is furnished with two unwind spools and film tensioners, a splicer assembly, and more.

HML 8 PROFILE LAMINATOR

Applies hot melt adhesives to the back of the various paper, foil, or vinyl webbings, and wraps the webbings around all types of profiled wood, extruded plastics, and metal substrates. The base hot melt wrapper is furnished complete with; two unwind spool and film tensioners, a splicer assembly, a hot melt adhesive applicator, and more.

HML 6 PROFILE LAMINATOR

Applies hot melt adhesives to the back of the various paper, foil, or vinyl webbing, and wraps the webbing around all types of profiled wood, extruded plastics, and metal substrates. The base hot melt wrapper is furnished with two unwind spool and film tensioners, a splicer assembly, a hot melt adhesive applicator, and more.

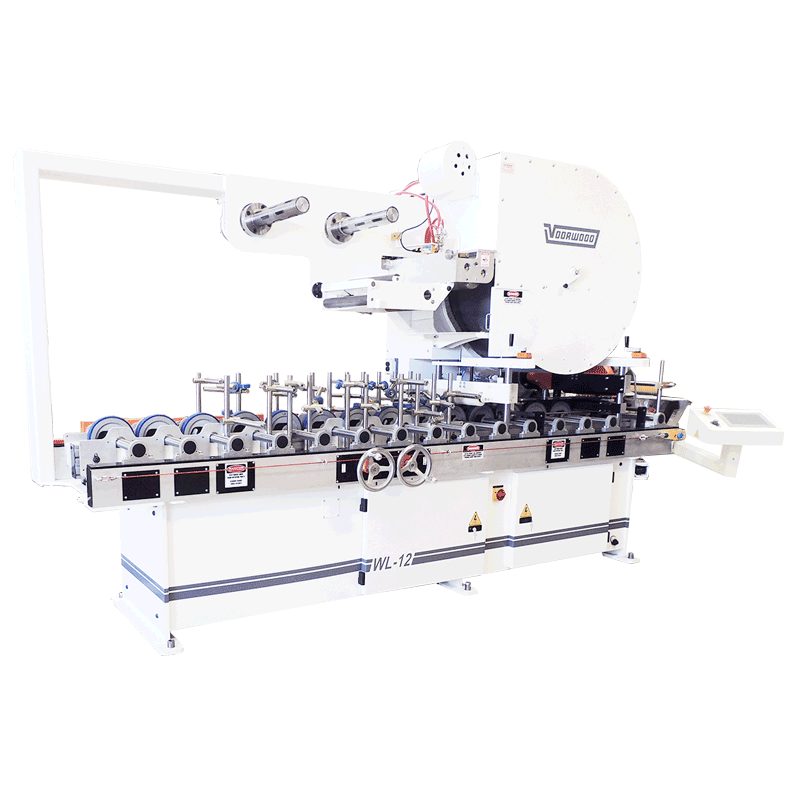

WL4 PROFILE WRAPPER

This compact laminator produces high-quality mouldings at up to 150 feet per minute. The unique quick-change cartridges enable complete pattern changeovers in less than five minutes. The WL4 combines proven technology, unparalleled customer service, and more than fifty years of experience in wrapping machinery.

Foilers

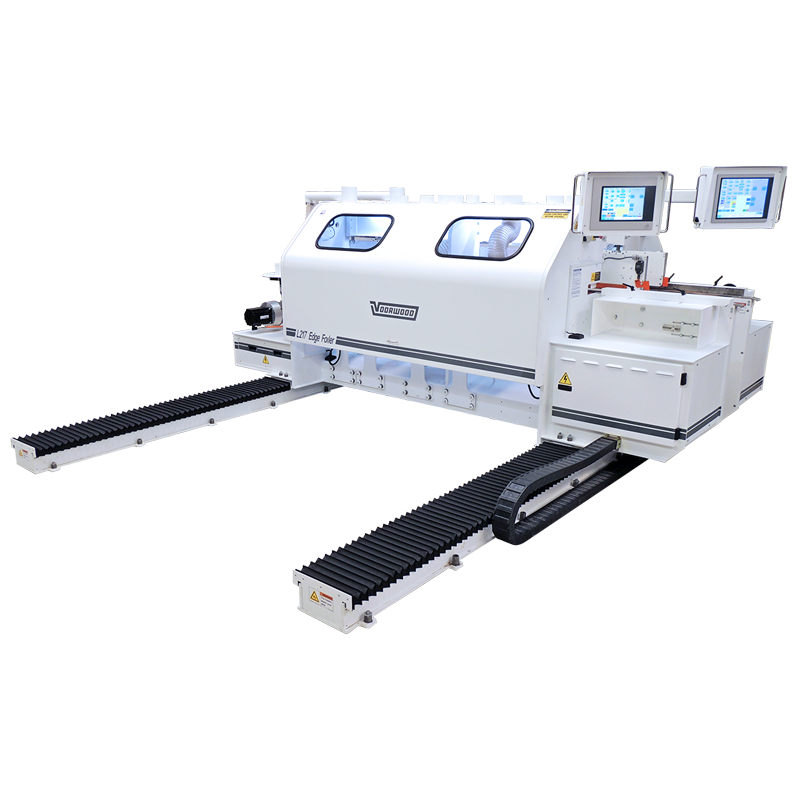

L217 DOUBLE-END FOILER

Profiles, sands, and applies dry-transfer finishing foil to both edges of MDF parts in one continuous pass. Designed for quick and easy changeover. Foiling stations equipped with 8˝ diameter foil wheels, non-contact sensors, and ovens for automatic temperature control. Optional top and bottom score saws to accurately score the part before shaping.

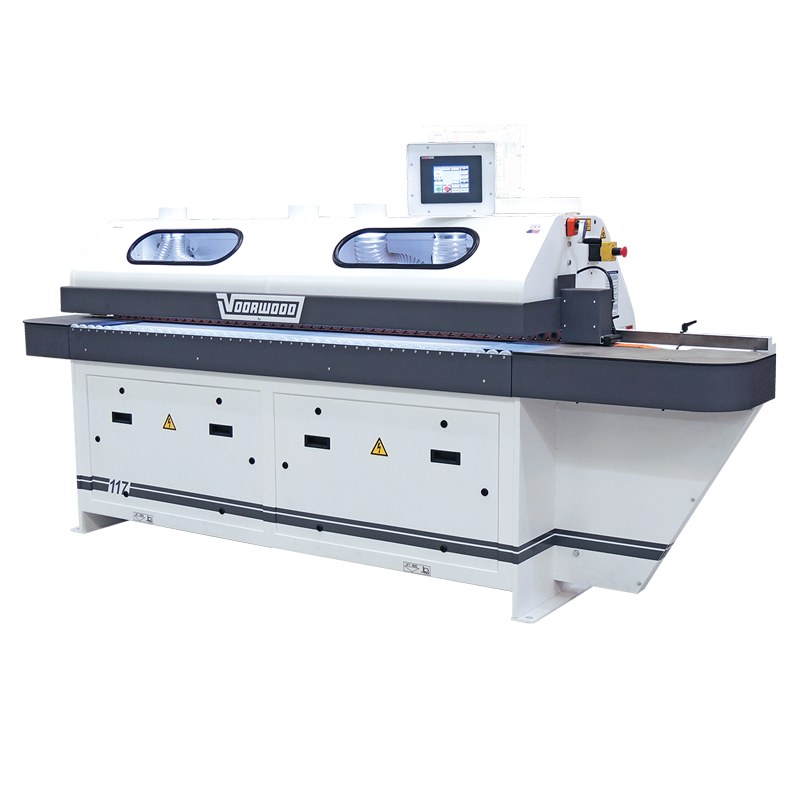

L117 EDGE FOILER

Shapes the profile, sands it smooth and applies the dry-transfer finish foil on MDF in a single continuous process. Stock is transported through the machine by a bottom-feed chain with special pads that grip the stock securely while it passes through the stations. The L117 Edge Foiler has digital readouts and micro-point tilt at the stations.

L115 EDGE FOILER

Shape the profile, sand it smooth and apply the dry-transfer finish foil on MDF consecutively in one continuous process. Stock is transported through the machine by a bottom-feed chain with special pads that grip the stock securely while it passes the stations. The L115 Edge Foiler has digital readouts and micro-point tilt at the stations.

L79 END FINISHER

Designed to precisely cut MDF louver parts to length, then sand both ends. Next, to complete the one-pass process, an applicator wheel with automatic heat control applies the transfer finish. A louver end foiler is a production-oriented machine designed for reliability and operator convenience using a hopper feeder.

P78 PLOUGH FOILER

Cuts a single plough (bluff cut) to the desired profile in an MDF drawer front or similar component and then sands and applies transfer finish to the plough, all in one pass. It does not require handwork, spraying, wiping, clean-up, or drying time. Parts exit the machine ready to be assembled or shipped. Saves time and money.

LUR27 CONVERTER LAMINATOR

Applies transfer-finishing foils to the surface of PVC. Hot-stamp foils have the look of real woodgrain finishes, marbles, granites, solid colors, and geometric designs. The laminator has two heated foil applicator stations, which are incorporated in a heavy-duty machine frame for durability and precision.

INSERT KNIVES

Voorwood Insert Knives have precise cutter blades built on the latest CNC wire EDM machines. Available in a variety of alloys including Carbide and Tantung. There are over 4,000 stock profiles available. Our engineers can duplicate your existing profile from a DXF file, CAD drawing, or wood sample.

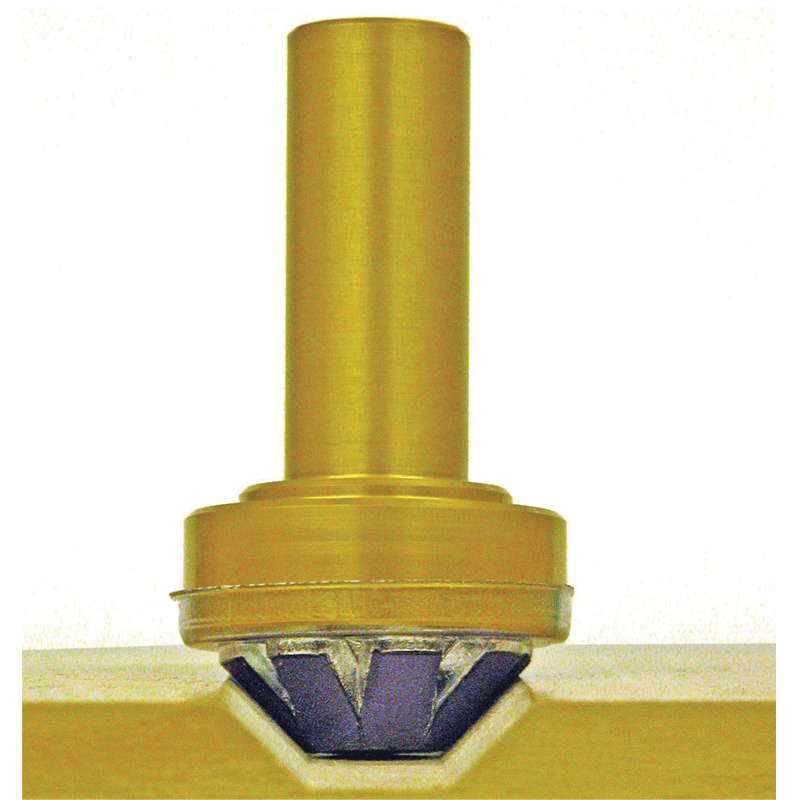

RAISED PANEL SHAPERS

Raised Panel Shapers with aluminum shaper bodies, custom profiled for the specified pattern and rotation. These are not reversible or interchangeable. Voorwood raised panel shaper tooling supports tenoners, foilers, shaper sanders, automated CNC routers, and spindle shapers. Voorwood offers a range of head diameters and widths.

TURBOSAND STRIPS

- Used to finish door-pulls, straight edges, bevels, bullnoses, corner rounds, coves, ogee, stile, waterfalls, and other more complicated contours

- Universal Head can sand many different profiles (sanding inserts with the same marking are interchangeable with the same head)

- Precision — Turbosand does not distort shapes or round-off sharp edges

TURBOSAND CAPS

- Designed for sanding deeper edge profiles at zero tilt angles

- Match deep reveals on doors

- Precise profile matching

- Simple two-piece sanding heads

- Sanding heads can be configured to fit any required spindle size (English or Metric bores). Common bores include 1-1/4”, 1-1/2”, 30mm, 35mm, and 40mm. The standard 1-1/4” bore can be adapted

TURBOFLEX PRO

TurboFlex Pro is a brush-backed abrasive rotary flap sander with the brush and the abrasive profiled to match your profile. This feature produces a higher quality and more uniform sanding of a profiled surface but does not over-sand high spots or round mitered corners as typically happens with straight line or non-profiled flap sanders.

FOIL WHEELS & ROLLERS

Hot-stamp Foils: Apply to a wide variety of substrates including solid wood, MDF, plywood, and solid surfaces. Available in a wide range of patterns included wood grain, sold color or clear. Dry Transfer Wheels: Foil wheels can be precision ground to match one of our stock profiles, matched to your profile, or provided as blanks.

Attachments

DSA DUAL SANDING ATTACHMENT

Created to help companies with existing transports to achieve high-quality profile sanding. The DSA is a rotary sanding attachment that has two counter-rotating heads to sand wood fibers smooth before finishing. Furnished with 3” long,938” (25mm) diameter spindles with double collets for accurate mounting of the rotary sander.

QUICK CHANGE SPINDLES

Quick Change Spindles for fast, easy, accurate, repeatable setups. The changeover takes less than a minute per spindle for the highest quality shaping and sanding before finishing! Unidirectional spindles have an expanding/contracting body that securely grips the shaper/sander heads.

RETURN CONVEYORS

Return Conveyors are designed to handle the fast pace of end-to-end feeding for shape/sand, single-end tenoner, and double-end tenoners. The feed rollers are driven by a variable-speed motor, guiding the part onto the receiving module. A set of top rollers provides a smooth transfer on the receiving module.

SS64 SIZE & SQUARE UNIT

An option offered with the Voorwood models A515, A517, A1515, and A1517 machines and is controlled with the touch screen on the parent machine. The operator of A115 or A117 machines that have their own touchscreens only needs to input the desired length and width of the substrate and the fence will automatically move to the correct position.